Hydraulic Testing Services

Hydraulic Testing

Hydraulic Testing, An Overview

Hydraulic Testing, An Overview

Hydraulic testing services encompass a vital aspect of ensuring the safety and reliability of hydraulic systems across various industries. This specialized service involves subjecting hydraulic components, equipment or systems to controlled pressure tests to assess their structural integrity, performance and adherence to regulatory standards. Hydraulic testing is essential for identifying potential leaks, weaknesses or malfunctions that could compromise the efficiency and safety of hydraulic systems.

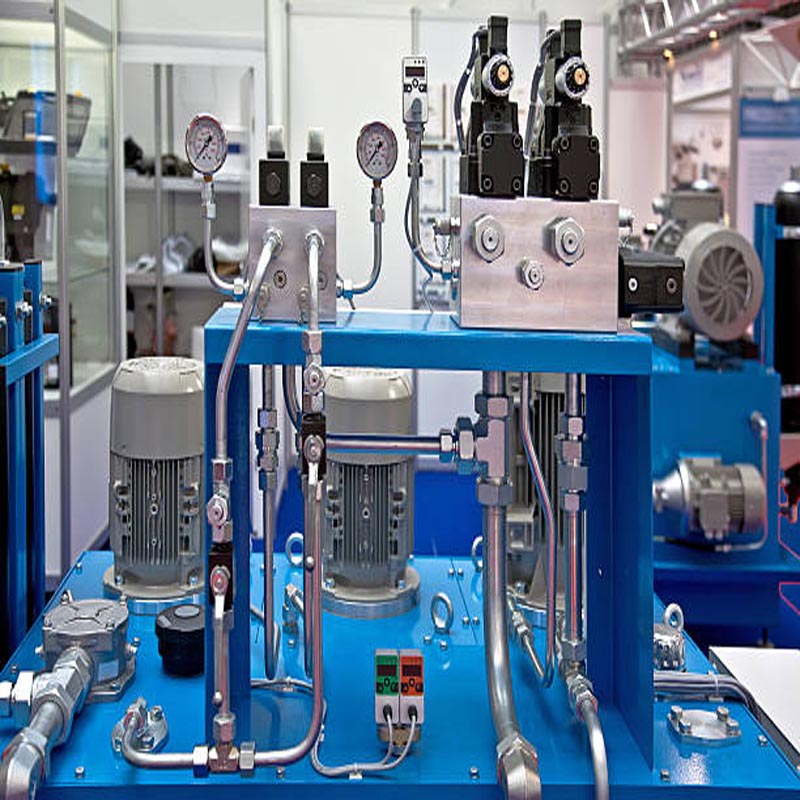

Our hydraulic testing services offer a comprehensive evaluation of the hydraulic systems underpinning your critical processes. Employing cutting-edge testing methodologies and equipment, we delve deep into the intricacies of your hydraulic infrastructure.

Our assessments encompass an exhaustive array of parameters, including pressure profiles, flow characteristics, and structural integrity. From hydraulic cylinders driving essential machinery to intricate valve networks regulating fluid dynamics, our meticulous testing protocols identify vulnerabilities and ensure the robustness of your hydraulic systems. With a keen focus on safety, reliability, and performance, our hydraulic testing services fortify your operations against potential risks and downtime, empowering you to navigate complex industrial challenges with confidence.

Hydraulic Testing Solutions By UTIC

Our Hydraulic Testing Solutions

Pressure Testing: Pressure testing involves applying hydraulic pressure to components or systems to verify their ability to withstand operating pressures without failure. This type of testing helps identify leaks, assesses the strength of materials and ensures compliance with pressure-related standards and regulations.

Leak Testing: Leak testing focuses on detecting and locating any leaks or fluid losses within hydraulic systems. This type of testing utilizes various methods such as pressure decay testing, bubble immersion testing or tracer gas testing to identify even the smallest leaks and prevent potential hydraulic failures.

Performance Testing: Performance testing evaluates the operational capabilities and efficiency of hydraulic systems under various conditions. It assesses factors such as flow rate, speed, power output, and response time to ensure optimal performance and functionality.

Functional Testing: Functional testing evaluates the overall functionality and operation of hydraulic components or systems, including valves, pumps, actuators and control systems. It verifies that all components perform their intended functions correctly and interact seamlessly within the hydraulic system.

Durability Testing: Durability testing assesses the long-term performance and reliability of hydraulic components or systems under continuous or cyclic operating conditions. It helps predict component lifespan, identify potential wear issues and optimize maintenance schedules to extend the service life of hydraulic equipment.Seal Testing: Seal testing evaluates the integrity and effectiveness of seals and gaskets within hydraulic systems. It ensures proper sealing to prevent fluid leakage, contamination and system failure, especially in high-pressure or critical applications.

Why UTIC for Hydraulic Testing

Selecting a reputable calibration service provider is crucial. Factors to consider include accreditation, expertise in specific calibration areas, turnaround time and the ability to provide comprehensive calibration certificates.

With a proven track record of excellence in calibration services, UTIC boasts state-of-the-art facilities and highly skilled technicians adept at calibrating a wide range of temperature instruments to the highest industry standards. Backed by years of experience and a dedication to quality assurance, choosing UTIC ensures accurate temperature measurements crucial for maintaining process efficiency, regulatory compliance and product integrity.